by Nikki Cabus | Apr 25, 2024 | Blog

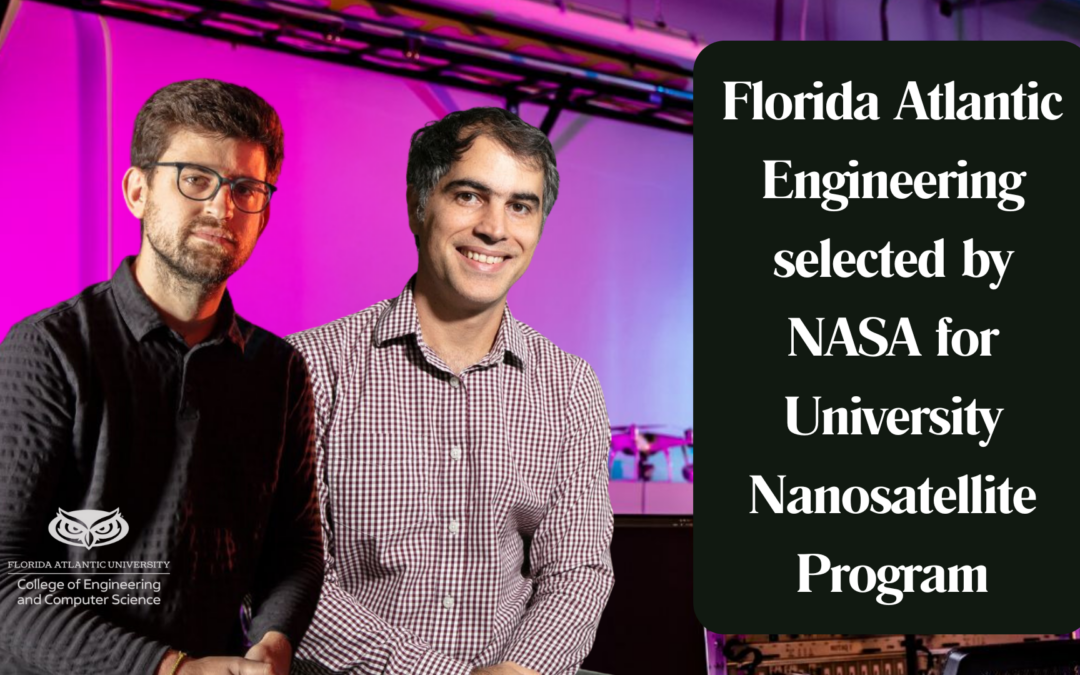

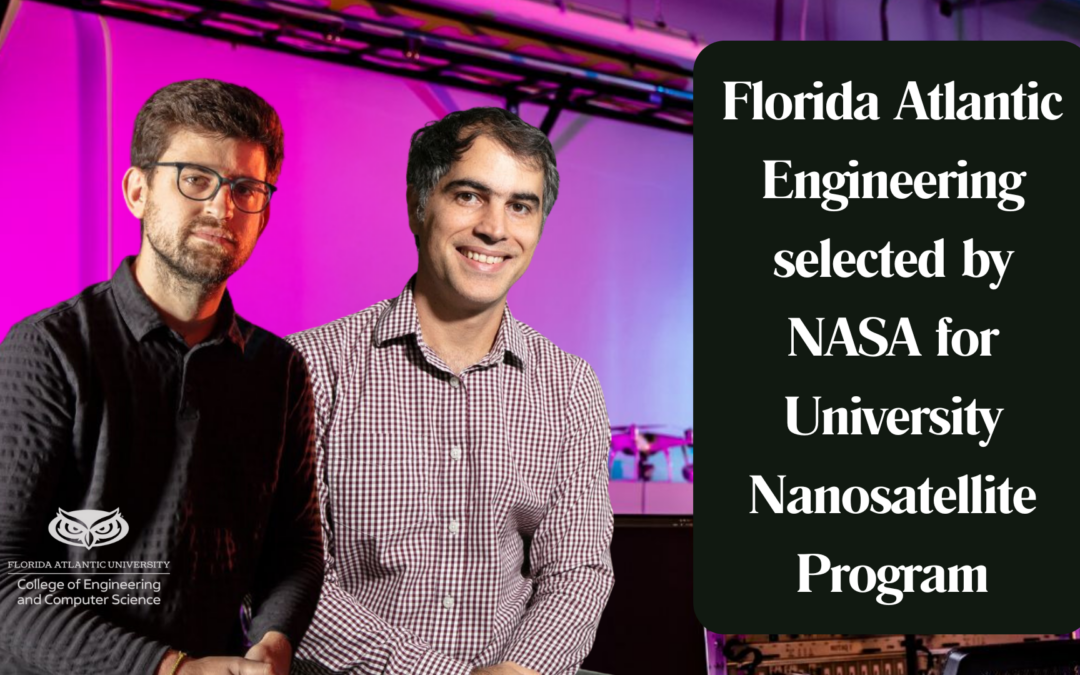

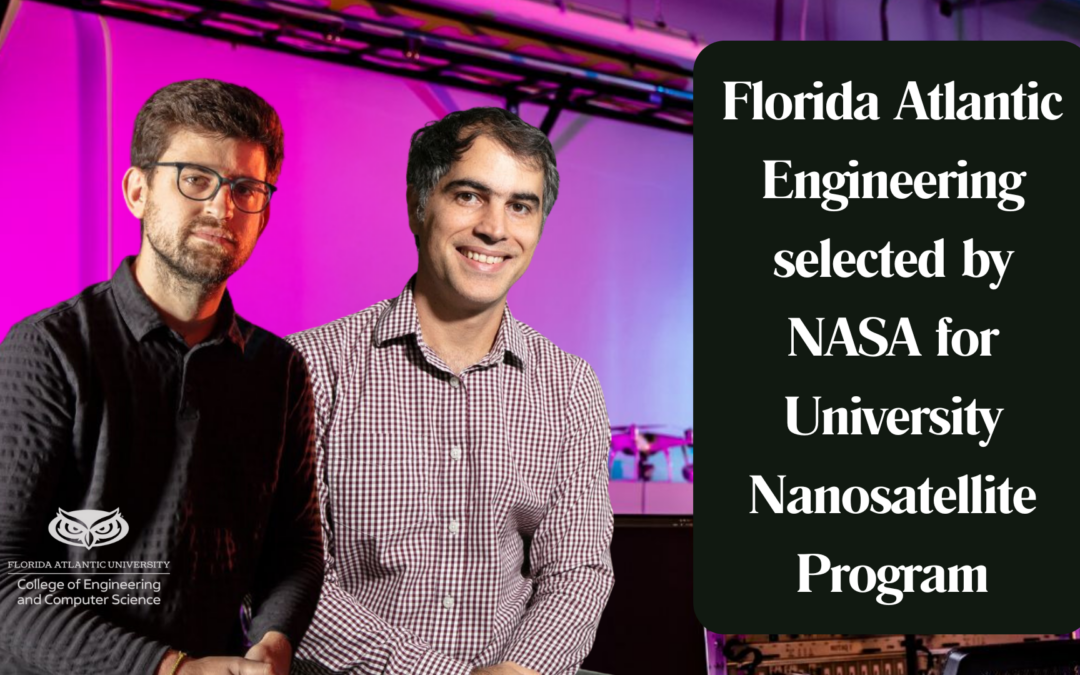

Florida Atlantic University’s College of Engineering and Computer Science is one of eight U.S. university teams chosen to collaborate with NASA – National Aeronautics and Space Administration and the U.S. military in advancing small satellite technology....

by Nikki Cabus | May 22, 2023 | Blog

Just last week Doroni Aerospace announced the exclusive launch of their Series A Reg D funding round available to accredited investors. Morgan Stanley research predicted that the eVTOL (electric vertical taken off and landing) market will reach over $1 trillion by...

by Nikki Cabus | May 2, 2023 | Blog

NASA is working to build a research base on the moon to send the first astronauts to Mars. Along the way, a new industry is coming to life: construction on surfaces beyond Earth. This is where master’s student Brandon Aguiar ’21 is launching his promising...